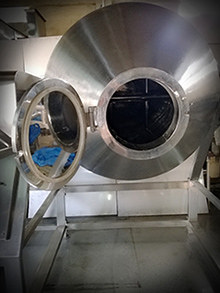

The platinum pharmatech Double Cone Blender is an efficient and versatile machine for mixing Dry powder and Granules homogeneously. All the contact parts are made of stainless steel. The effective volume for optimum homogeneity is between 35-70% of gross volume. The SLANT double cone design eliminates dead spots, which regularly occur in conventional double cone mixers. The Double Cone Blender can be used in pharmaceutical, Food processing, Chemical and Cosmetics preparation Industries.

Application

- Mixing Dry drugs in powder forms in the production of Tablets and Capsule based formulations

- Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet granules.

Features

- The Conical shape at both ends enable Uniform Mixing and easy discharge.

- The Cone is designed to achieve Static Equilibrium to avoid Excessive loads on the gear box and Motor.

- While the powder can be loaded into the cone through a wider opening, it can be discharged through a butterfly or slide valve.

- Depending upon the product, paddle-type baffles can be provided on the shaft for better mixing inside the cone.

- The contact parts are made of either SS 304 or SS 316.

- Flame proof motor can be supplied as an option.

- Available in 50 and 4000 liters capacity.

- The working capacity can be Changed to 80% of gross capacity by validated study depending on the product being manufactured.

- 'Slant' design (off- centric) Double Cone Blender is also available.

- Hand wheel will be provided for Tilting the Cone manually.

- All safety guards & covers made out of SS304 in GMP Model .

- The Blender is built to ensure safety of operations.

- All joints are argon arc welded and all SS parts are polished to mirror finish, required of pharmaceutical equipment. MS parts are painted to smooth finish.

- Dust free Bin charging system ensures Minimum Material wastages (?)

Technical Specifications

Model |

Gross |

Working In Ltrs |

RPM |

HP |

Gear Box |

Discharge |

Overall Dimension |

PPTDCB-15 |

15 |

11 |

6-36 |

0.5HP |

0.5SNU |

75 |

850 x 650x 1200 |

PPTDCB-25 |

25 |

20 |

6-36 |

0.5HP |

0.75SNU |

75 |

850 x 650x 1200 |

PPTDCB-50 |

50 |

30 |

6-36 |

0.1Hp |

0.1 SNU |

100 |

1200x950x1650 |

PPTDCB-100 |

100 |

65 |

6-36 |

1HP |

1.76SNU |

150 |

1500x1000x 1800 |

PPTDCB-200 |

200 |

135 |

6-36 |

3HP |

2”SNU |

150 |

2000x1200x2250 |

PPTDCB-300 |

300 |

200 |

6-36 |

3HP |

3 SNU |

200 |

2100x1400x2350 |

PPTDCB-400 |

400 |

280 |

6-36 |

3HP |

3 54SNU |

200 |

2200x1400x2350 |

PPTDCB-500 |

500 |

350 |

6-36 |

5HP |

4 ” SNU |

200 |

2350x1500x2500 |

PPTDCB-800 |

800 |

600 |

6-24 |

5HP |

4” SNU |

200 |

2550x1600x2800 |

PPTDCB-1000 |

1000 |

750 |

6-24 |

5HP |

5 SNU |

200 |

2700x1800x3000 |

PPTDCB-1500 |

1500 |

1000 |

6-24 |

7.5HP |

7 SNU |

250 |

3000x2200x3400 |

PPTDCB-2000 |

2000 |

1400 |

6-24 |

10HP |

8” SNU |

250/400 |

3250x2400x3550 |

PPTDCB-2500 |

2500 |

1750 |

6-24 |

15HP |

8” SNU |

250/400 |

3400 x 2600x3700 |

PPTDCB-3000 |

3000 |

2100 |

6-24 |

15HP |

9” SNU |

250/450 |

3600 x 2750x 3850 |

PPTDCB-4000 |

4000 |

2800 |

6-24 |

20HP |

10” SNU |

250/500 |

4200 x 3000x 4500 |