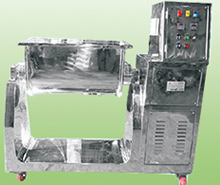

The Platinum pharmatech Ribbon Blendercomprises of a U-shaped horizontal trough and a Double Helical Ribbon Agitator rotating within. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are well balanced to provide movement of material within the container and prevents dead spots and delivers rapidly the product.

An alternate design is the paddle agitator. The paddles are positioned to move the material in opposing lateral directions as well as radically. The paddle design is generally employed where Friable materials are being blended, and when batches as small as 15% of the total capacity are going to be mixed in the blender.

Standard Features:-

- Available in working capacity of 5 liters - 5,000 liters.

- Available in all grades of stainless steel, carbon steel and special alloy steels.

- Ribbon agitator for center discharge are designed for atmospheric operations.

- Top cover depending on the length of the blender.

- Centrally located Flush bottom discharge valve.

- Stuffing boxes with easily disassembled housings.

- Teflon gland packing provided.

- Stainless steel surfaces are polished to desired standards. All exterior non-stainless surfaces are painted with enamel paint.

- Squirrel Cage, Three Phase Induction Motors suitable for 415 Volts, and 50 Hz. Worm Reduction Gearbox. Single Speed Drive Blender is mounted on supports providing adequate discharge clearance.

- Available in working capacity of 5 liters - 5,000 liters.

Technical Specifications

Model |

G. Cap Ltrs |

W. Cap in Kgs |

HP |

Gear Box |

PPTRB50 |

50 |

20 |

1 HP |

0.75SNU |

PPTRB75 |

75 |

30 |

1HP |

1.75SNU |

PPTRB150 |

150 |

55 |

2HP |

3”.SNU |

PPTRB250 |

250 |

95 |

3HP |

3.54”SNU |

PPTRB450 |

450 |

170 |

5HP |

5 “SNU |

PPTRB600 |

600 |

225 |

7.5HP |

6”SNU |

PPTRB1000 |

1000 |

375 |

10HP |

6”SNU |

PPTRB1500 |

1500 |

565 |

12.5HP |

7”SNU |

PPTRB2000 |

2000 |

750 |

15HP |

7”SNU |