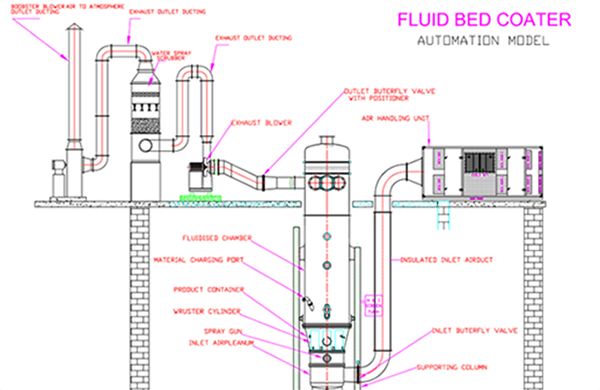

The Platinum Pharmatech Fluid Bed Coater is specially designed for coatings the pellets. The basic concept of the Processor begins with a simple dryer unit, to which several different optional packages may be added to attain granulation, film coating and pellet coating. This is upto 400% faster than the conventional coating methods.

- The Single Pot Technology has changed the conventional method of Granulation into Safer, Well Contained and incorporates quality process with increasing yields. Thus Fluid Bed Coater can replace RMG, FBD, Multi-Mill and Blender.

- All in one piece of equipment: Dry Mixing, Drying, Wet Granulation, Blending and Pellet Coating

- Suitable for: Granulation/Drying, Pellet (Controlled-Release Coating): Film Coating, Enteric Coating and Powder Coating

The Uber Modern Process Engineering -explained

In the Fluid Bed Coater, particles are fluidized and the coating fluid sprayed and dried.

Small droplets and a low viscosity of the spray medium ensures an even product coating. This process equipment replaces a number of conventional machinery,

resulting in substantial savings in terms of Space, Energy, Manpower, Yield and Air conditioning costs, while ensuring Shorter cycle times.

Yield attains 100% increase, with negligible handling losses due to single pot design, Sophisticated PLC controls ensure high

degree of Control of Process parameters ensuring Batch replication. The FBC is ensures ease in Validation, Highest degree

of Safety, while the Sampling Port facilitates drawal of samples for in-process quality control tests, without

interrupting the fluidization process. Excellent design & control of the Inlet Air Handler, ensure clean processing air at all

times with no contamination.

* R&D FBC 1-5 Kg Model with Auto Manual & PLC

* Production scale FBC 50 - 1000 liters (45 to 600 Kgs) capacities with PLC as an Option. While it is 1 -10 liters ( 1 -5 Kgs) for Scaled or R&D model

Features

- The conical shape at both ends enable uniform mixing and easy discharge

- The cone is statically balanced to prevent excessive load on the gear box and motor

- While the powder can be loaded into the cone through a wide intake, it can be discharged through a butterfly or slide valve

- Depending upon the product, paddle-type baffles can be provided on the shaft for better mixing inside the cone.

- The contact parts are made of either SS 304 or SS 316

- Flame proof motor can be supplied as an option

- Designed Capacity range from 50 to 4000 Liters

- The working capacity can be exchanged to 80% of gross capacity by validated study depending on the product.

- 'Slant' design (off center Double Cone Blender is also available)

- Hand wheel will be provided for manual tilting of cone

- All safety guards & covers made out of SS 304 in The cGMP Model

- Maximum care has been taken to ensure safe operation of the unit.

- All joints are argon arc welded and all SS parts are polished to mirror finish, required for pharmaceutical equipment, while MS parts are painted to smooth finish

Technical Specifications

MODEL |

VOLUME |

WORKING CAPCITY |

MOTOR/RPM /MAKE |

BLOWER CFM |

NO.SPRAY GUNS |

PPTR&D FBC1-5KG |

5 |

10 |

2HP/2880/CG |

2000 |

1 |

PPT FBC-45KG |

45 |

90 |

5HP/2880/CG |

3000 |

1 |

PPT FBC-60KG |

60 |

120 |

7.5HP/2880/CG |

4000 |

1 |

PPT FBC-90KG |

90 |

180 |

7.5HP/2880/CG |

4000 |

1 |

PPT FBC-120KG |

120 |

240 |

10HP/2880/CG |

4000 |

1 |

PPT FBC-150KG |

150 |

300 |

12.5HP/2880/CG |

5500 |

1 |

PPT FBC-180KG |

180 |

360 |

12.5HP/2880/CG |

5500 |

1 |

PPT FBC-200KG |

200 |

400 |

15HP/2880/CG |

5500 |

1 |

PPT FBC-250KG |

250 |

500 |

15HP/2880/CG |

5500 |

1 |

PPT FBC-300KG |

300 |

600 |

30HP/2880/CG |

5500 |

1 or 3 |

PPT FBC-500KG |

500 |

1000 |

50HP/2880/CG |

6000 |

5 |