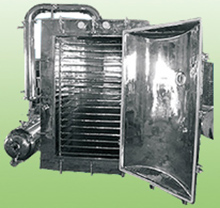

The PlatinumPharmatech Vacuum Tray Dryer works under vacuum conditions. It achieves uniform drying by conduction. There are a number of shelves inside the dryer on which the trays containing products are placed. The top most shelf is a redundant shelf to ensure proper heating and it serves to block dried powder from escaping into the solvent extraction system.

The shelves are manufactured in hollow construction with baffles cum stiffeners placed in between. Each shelf has an inlet and outlet nozzle. Each shelf is connected through these nozzles to an Inlet and Outlet Header. Hot media is passed through the Inlet Header and in turn to each shelf. The hot media flows through the shelves in a zigzag manner ensuring faster heat transfer to the surface, which in turn heats up the Trays placed on the shelves. The hot media flows out from the shelves through the Outlet Header. The Inlet and Outlet Headers are designed such that the flow of the heating media is equally distributed into the each of the shelves. The Dryer chamber is constructed with heavy thickness plates to ensure that there is no buckling during the vacuum operation. Additional limpet coils are provided to further stiffen the body and also to pass the hot media. The chamber is secured with a heavy door and locking. The Dryer chamber is connected through a vapor column to a Shell ET Tube type Heat Exchanger, which in turn is connected to a Condensate Receiver. Vacuum is applied to the condensate receiver. Vapor formed during the drying process is collected in the receiver after it is cooled in the Heat Exchanger.

The vapor collected is passed through the Heat Exchanger. While cooling water is passed through the shell side. A cooling coil is present in the condensate receiver, to further cool any vapors entering the receiver before it passes into the vacuum pump. The Condensate receiver is connected to a Vacuum Trap, to ensure that any uncooled vapors coming from the receiver is trapped and prevents vapor to pass into the Vacuum Pump.

Design C Temperature: 150 Degree Centigrade

Testing: The Vacuum Dryer Shelves Are Hydro-tested 5 Kg/Cm2 In Assembled Condition. The Vacuum Chamber Is Tested For Full Vacuum.

Technical Specifications

MODELS |

Capacity in Kgs |

No of Doors |

Vacuum Pump Cap |

condenser |

Receiver |

No. Heating shelf’s |

Trays on Each Self |

PPT-VTD3 |

3-5- |

One |

0.5HP |

0.2m2 |

10Ltrs |

1 |

3 |

PPT-VTD6 |

12-18 |

One |

0.5HP |

0.5 m2 |

25 Ltrs |

2 |

3 |

PPT-VTD12 |

25-35 |

One |

2 HP |

0.75 m2 |

50 Ltrs |

5 |

3 |

PPT-VTD24 |

50-75 |

One |

3 HP |

1m2 |

75 Ltrs |

9 |

3 |

PPT-VTD36 |

75-100 |

One |

3HP |

1.5m2 |

100 Ltrs |

13 |

3 |

PPT-VTD48 |

100-150 |

One |

3HP |

2m2 |

150 Ltrs |

17 |

3 |

PPTVTD 96 |

200-300 |

Two |

5HP |

3m2 |

250 Ltrs |

25 |

4 |